주메뉴

- About IBS 연구원소개

-

Research Centers

연구단소개

- Research Outcomes

- Mathematics

- Physics

- Center for Underground Physics

- Center for Theoretical Physics of the Universe (Particle Theory and Cosmology Group)

- Center for Theoretical Physics of the Universe (Cosmology, Gravity and Astroparticle Physics Group)

- Dark Matter Axion Group

- Center for Artificial Low Dimensional Electronic Systems

- Center for Theoretical Physics of Complex Systems

- Center for Quantum Nanoscience

- Center for Exotic Nuclear Studies

- Center for Van der Waals Quantum Solids

- Center for Relativistic Laser Science

- Chemistry

- Life Sciences

- Earth Science

- Interdisciplinary

- Center for Neuroscience Imaging Research (Neuro Technology Group)

- Center for Neuroscience Imaging Research (Cognitive and Computational Neuroscience Group)

- Center for Algorithmic and Robotized Synthesis

- Center for Genome Engineering

- Center for Nanomedicine

- Center for Biomolecular and Cellular Structure

- Center for 2D Quantum Heterostructures

- Institutes

- Korea Virus Research Institute

- News Center 뉴스 센터

- Career 인재초빙

- Living in Korea IBS School-UST

- IBS School 윤리경영

주메뉴

- About IBS

-

Research Centers

- Research Outcomes

- Mathematics

- Physics

- Center for Underground Physics

- Center for Theoretical Physics of the Universe (Particle Theory and Cosmology Group)

- Center for Theoretical Physics of the Universe (Cosmology, Gravity and Astroparticle Physics Group)

- Dark Matter Axion Group

- Center for Artificial Low Dimensional Electronic Systems

- Center for Theoretical Physics of Complex Systems

- Center for Quantum Nanoscience

- Center for Exotic Nuclear Studies

- Center for Van der Waals Quantum Solids

- Center for Relativistic Laser Science

- Chemistry

- Life Sciences

- Earth Science

- Interdisciplinary

- Center for Neuroscience Imaging Research (Neuro Technology Group)

- Center for Neuroscience Imaging Research (Cognitive and Computational Neuroscience Group)

- Center for Algorithmic and Robotized Synthesis

- Center for Genome Engineering

- Center for Nanomedicine

- Center for Biomolecular and Cellular Structure

- Center for 2D Quantum Heterostructures

- Institutes

- Korea Virus Research Institute

- News Center

- Career

- Living in Korea

- IBS School

News Center

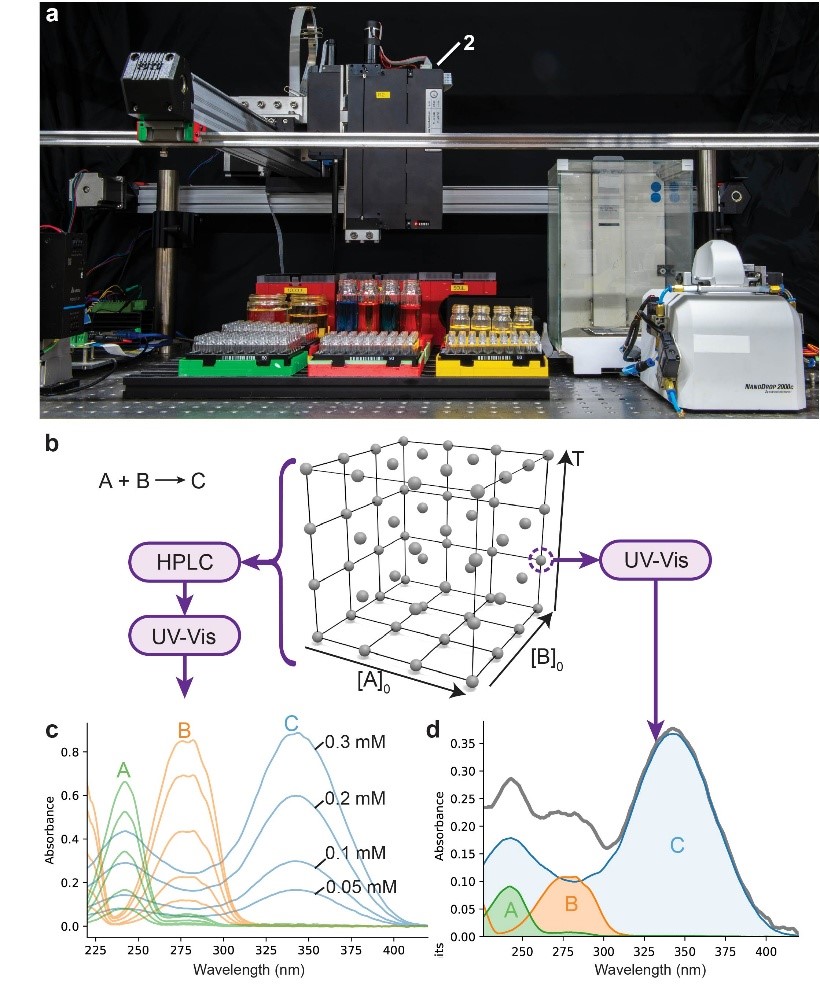

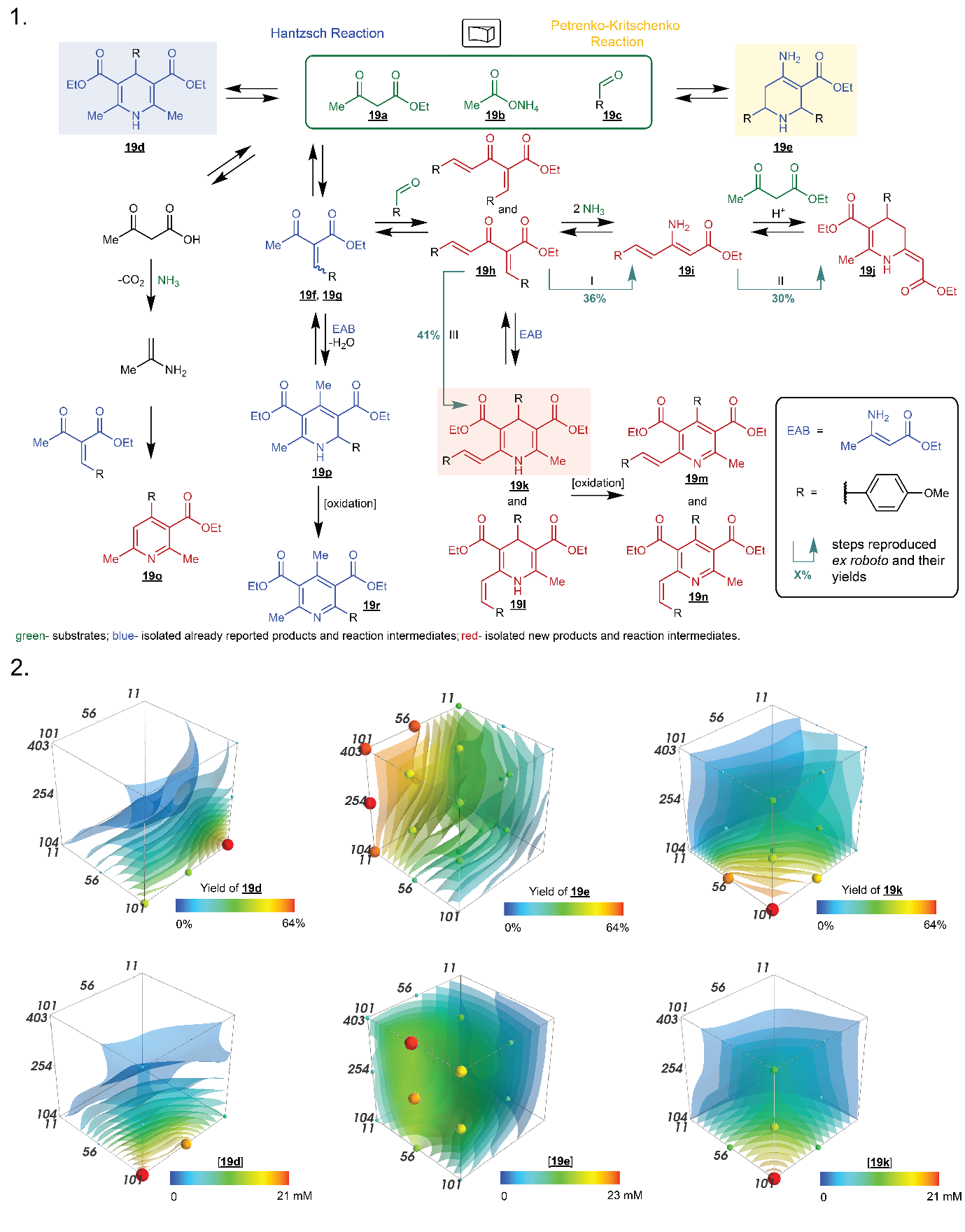

Robots Map Chemical Reaction “Hyperspaces” to Unlock Complex Networks- New low-cost robotic platform creates detailed maps of chemical reactivity, revealing paths to hidden products and new strategies to guide chemical synthesis - Traditionally, chemical reactions have been described as one-line “equations” in which substrates, say A and B, convert purposefully but rigidly into a desired product, say C. Naturally, it has been recognized that byproducts may also form, but these have been generally considered undesirable and unproductive. The current research demonstrates that this view is very fragmentary and insufficient: in reality, chemical reactions – even those studied since the 19th century – are complex reactivity networks that, depending on the concentrations of substrates and temperatures, can be steered towards different outcomes and even switched between different major products. This is reminiscent of how biology operates its vast networks of enzymatically controlled reactions, dynamically switching them between different outputs under different cell statuses. Now, the formulation of chemical reactions as such dynamic networks sets the foundation for the study of “intelligent chemical soups,” in which the same components – but under different conditions – can give profoundly different products, thereby conserving use of chemical feedstocks while maximizing diversity of outputs. Led by Professor Bartosz A. GRZYBOWSKI, researchers at the Center for Robotized and Algorithmic Synthesis (CARS) within the Institute for Basic Science (IBS) in Ulsan, South Korea, put their robots to the challenge and extend the traditional view of chemical reactions. Historically, such reactions have been represented as one-line formulas describing the conversion of substrates into a desired and rigidly defined major product, with byproducts acknowledged but undesirable and generally considered unproductive. The CARS work, to be published in Nature on Sept 24, tells us that reactions should be thought of as complex networks programmable to yield different products under different conditions. The springboard for the CARS work was sheer scientific curiosity – how well would the traditional view hold when reaction conditions change over a broad range? Would the same product always dominate? Or maybe, under some conditions, one of the byproducts could take over and become the major product? Surprisingly, although many chemical reactions have been studied for decades, there have been no general-scope answers to such questions. This is in large part due to the fact that human chemists have explored only a very small fraction of the vast space of possible conditions. Indeed, even for the simplest reaction, say A + B C, surveying ten concentrations of A, ten concentrations and B, and maybe ten temperatures already translates into a space of 10 x 10 x 10 = 1000 experiments and analyses of reaction outcomes, which, as chemists very well know, are laborious and expensive. No wonder human researchers have never been enticed into this kind of Benedictine work. But if humans are unwilling, maybe robots could give it a try? Accordingly, the CARS team set out to construct an inexpensive robotic system that would not only be able to set up thousands of reactions (which is relatively easy) but could also analyze in quantitative detail the compositions of the reaction mixtures (and this is hard). To do this, they designed an ingenious method that relies on very rapid optical detection and minimizes the use of traditional – and much slower and more expensive – analytical methods such as NMR or HPLC. Colloquially put, they managed to estimate concentrations of different products and byproducts in a reaction vessel by simply taking its photograph (technically, an optical spectrum). In this manner, they were able to set up and analyze up to 1000 reactions per day, a throughput unmatched by any other system. With this robotic platform in hand, they began to systematically probe multidimensional “hyperspaces” of conditions – from three to five dimensions defined by substrate concentrations and/or temperatures. What they started discovering was quite startling, as the hyperspaces of different reactions consistently housed regions of unexpected outcomes (i.e., products never seen before). In several cases – even in “classic” reactions studied for well over a century and in, apparently, exhaustive detail – the number of new products thus discovered more than doubled the existing knowledge, with as many as 15 species formed. Clearly, such rich reactivity landscapes could no longer be described as A + B C, formulas – instead, they must be construed as intricate networks! At this stage, the researchers knew which condition “inputs” led to different reaction “outputs,” but they did not yet know the connectivity of the underlying reaction networks. For this, they took inspiration from electronics, in which the connectivity of an unknown, “black-box” circuit can often be deduced from input-output characteristics. Adapting their kinetic and chemical AI algorithms to this problem, the CARS team was able to reconstruct intricate reaction networks in quantitative detail. Moreover, with this knowledge, they were able to control these networks in such a manner that the same set of starting materials could – under different conditions – be steered to form different major products. In other words, they managed to achieve network switchability, which is the cornerstone of biological networks (adapting their functioning and outputs to external conditions), but has never been purposefully engineered in chemistry. This finding has profound repercussions, especially at times when resources and scarce and need to be conserved. In essence, the CARS findings tell us that we can minimize the use of chemical feedstocks and reprogram them to products, under different conditions, different products, including those featuring important, functional scaffolds seen in drugs, pigments, and even organic-electronic materials. This kind of adaptive production of chemicals has been one of the hallmarks of living organisms – now, owing to the combination of robotics and chemical AI, it is being realized in chemistry! In a broader context, this work is the first step into the DarkNet of chemical reactivity – that is, new patterns of reactivity hidden in multidimensional “hyperspaces” of conditions. Despite decades of study, this DarkNet has remained elusive but is now open for fruitful, robotized exploration. This study marks a step change in how we study and control chemical reactions. By combining robotics with simple, rapid forms of detection, the team was able to explore thousands of reaction conditions at once and create detailed maps of how outcomes shift across chemical hyperspaces. These maps revealed not only predictable patterns but also surprising discoveries — including hidden reaction products and the ability to “switch” between entirely different outcomes simply by adjusting the starting ratios of ingredients. The implications extend well beyond the laboratory bench. For researchers, this approach provides a powerful new lens to understand the logic of chemical reactivity, turning reactions into navigable landscapes rather than isolated events. In short, this work provides a foundation for a future in which chemistry can be explored and guided with the same precision and scalability as modern data science.

Notes for editors

- References

- Media Contact

- About the Institute for Basic Science (IBS) |

| before |

|---|

- Content Manager

- Public Relations Team : Yim Ji Yeob 042-878-8173

- Last Update 2023-11-28 14:20